Hydro wants to use the technology pilot in Karmøy to roll out the world's most energy and climate-efficient technology for producing aluminum.

Compared with the world average, the technology developed by Hydro's researchers reduce energy consumption in aluminum production by 15 percent. The low energy consumption, coupled with high productivity, means that Hydro can safely say that the technology pilot in Karmøy is world leading in primary aluminum production.

In December 2020 a two-year internal testing program successfully verified the HAL4e production technology. Twenty of the 60 HAL4e pots were selected for the final performance test, which was conducted for 75 days between October and December. During the test period, a range of additional measurements were performed on a number of parameters and exact production figures were traced and recorded. The energy results came in at 12.27 kWh/kg Al – below the set target of 12.3 kWh/kg Al.

Technology developed by Hydro

Hydro is a world leader in research and development in the aluminum industry. In recent years the researchers in Hydro's technology centers in Årdal, Porsgrunn and Neuss in Germany have developed the next generation in electrolysis technology which will reduce energy consumption and emissions in the aluminum industry. It is this technology that is now being tested in a full scale production plant.

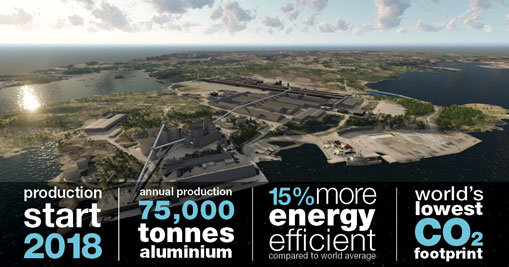

75,000 tonnes of aluminum per year for cars and buildings

The pilot facility is built at Hydro's existing aluminum plant in Karmøy in Rogaland County, Norway. The pilot adds 75,000 tonnes of aluminum production per year to the existing capacity of approximately 200,000 tonnes.

Hydro Karmøy produces aluminum products used in plates and profiles in the construction and automotive industries, and aluminum wire for high voltage lines, among other applications.

Updated: May 15, 2024