Forged aluminium is ideal when your component requires both performance and safety, and light weight for energy efficiency.

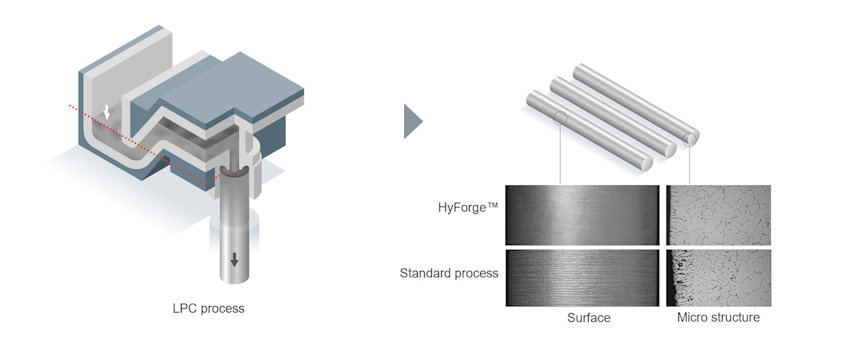

More car manufacturers use closed die forging to make parts in for example wheel suspensions. With the new low pressure casting (LPC) technology Hydro can offer a new high-quality forge stock. The main benefit of the LPC technology is that friction which is normally occurring on the ingot surface is eliminated resulting in a very smooth surface of the log. The inverse segregation zone is also eliminated. As a result, there is no need for further process steps like scalping, extrusion or machining. The HyForge™ material can be used directly in the forging process.

HyForge™ is delivered with a certified low carbon footprint according to the Hydro REDUXA 4.0 certificate. Hydro REDUXA 4.0 sets a new standard for carbon footprint in production of aluminium.